CO2 Pipelines

Presented by: Toan Nguyen & Balaji Ramarao

UPI is committed to enhancing the global energy market and helping companies mitigate greenhouse emissions. Carbon capture, transportation, and storage help the low carbon footprint economy and spur transforming CO2 gas into an economic resource for energy operations.

Carbon dioxide (CO2) pipeline transportation and facilities are crucial infrastructure to move carbon capture to geological storage or put to beneficial use, such as enhanced oil recovery in oil and gas operations and other industrial use. Industrial and commercial investment opportunities include facilitating CO2 pipeline infrastructure planning, siting, and permitting.

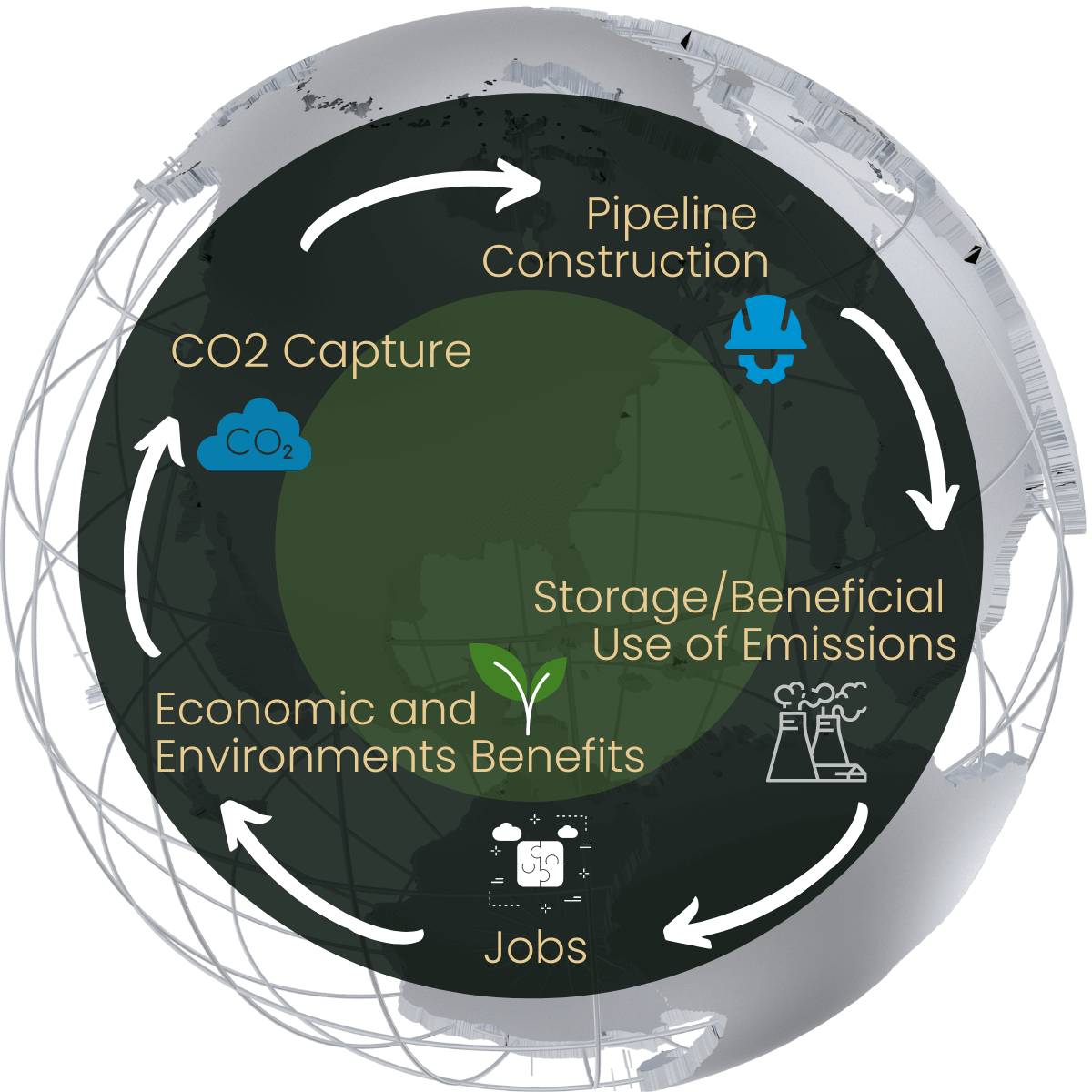

The US has about 5,000 miles of CO2 pipeline networks in the Permian Basin, Gulf Coast, Rocky Mountains, and Mid-continent, and is poised to expand the pipeline infrastructure and facilities. The below chart provides overall perspective of Carbon Capture Circular Economy.

Enhanced Oil Recovery

Enhanced oil recovery using CO2 miscible floods started in Texas in 1970.

Over 56 oil fields are currently using CO2 enhanced recovery and collectively produce over 200,000 barrels per day of crude oil.

Water and CO2 are injected alternately into the injection wells. The injected CO2 enters the reservoir and

moves through the rock’s pore space. Droplets of crude oil become miscible and form a concentrated oil

bank and flow towards the producing wells. The produced fluids flow through the separator to separate oil,

water, and gas. The produced gas treated to recover CO2, and the wet CO2 is dehydrated, compressed, and recycled back for injection. Additional CO2 is also injected for makeup to compensate for the recycle recovery. A supply/distribution pipeline delivers makeup CO2. The facilities include a meter station and booster pump to comingle the CO2 at the required pressure.

Carbon Capture

About 13 commercial carbon capture plants in the US capture approximately 25 million tons of CO2.

Post-combustion flue gas is absorbed with solvent, and the recovered CO2 rich solvent goes through a regenerator to recover CO2. The CO2 gas is treated, dehydrated, and compressed for transport in a pipeline.

CO2 Pipelines

CO2 pipelines operate in different regions of the vapor-liquid equilibrium (VLE) phase envelope. Some pipelines operate in the dense phase region (above 1250 psig) and use booster pump stations to transport CO2 in long distance and interstate pipelines. Other pipelines operate in the gas phase (low pressure) and use compressors to transport the gas.

Design considerations include the following: